Working

Techniques and Repair Methods for Plaster Decorations on Facades

By: Søren Vadstrup

4. Decorated

flat plaster on facades

Variations - surfaces and decorations

Flat plaster surfaces on facades

is seldom just flat plaster. The deliberate choice of gravel and sand for

the mortar influences on the colour and texture of the finished plaster.

This "natural coloured" plaster can be brown, grey, brown-grey, brownish,

yellowish, reddish - as the gravel materials itself.

The next decorating step is to colour

the mortar with pigments. This enable the plaster to be yellow, red, red-brown,

green, black-grey and white.

The third step is to give the plaster

a surface treatment of colours, made by paint or lime wash all over the

surface. But this materials can also manifest itself in artistic decorations

in lime technique (al secco) or in linseed oil technique.

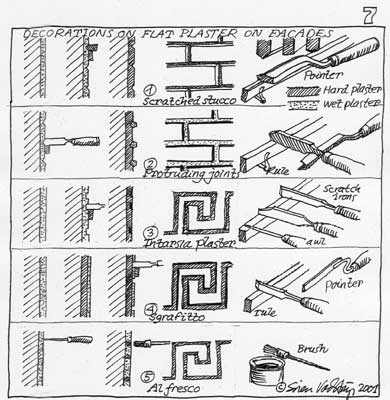

More sophisticated decorations can

however achieved by decorating the flat /plaster itself, by 5 various techniques:

1 Scratched stucco-decoration

2 Protruding pointings

3 Inlay/intarsia plaster decorations

4 Sgrafitto decorations

5 Al fresco decorations

Materials

The materials for these techniques

are mainly wet slaked air lime mortar (air lime and gravel 1:3) or hydraulic

mortar (air lime, hydraulic lime and gravel 1:1:6). Portland cement mortar

will tend be a too hard and stiff material for this purpose.

To obtain and ensure a sufficient

flexible and workable mortar, the wet slaked lime has to be matured for

at least 3 years in a frost free lime kiln, very fine grained and without

any sort of dirt or impurity.

Also the gravel and sand has to

be carefully selected, sieved, washed and without any impurities.

Even the water must be very clean

and without any salts etc. Best is distilled water, so in previous times,

the masons gathered rainwater in special wooden barrels. The same is recommended

to day. Air lime mortar, made with use of rain water, carbonate even more

slowly than else, and could therefore be worked in with sgrafitto, intarsia

and alfresco for a longer period.

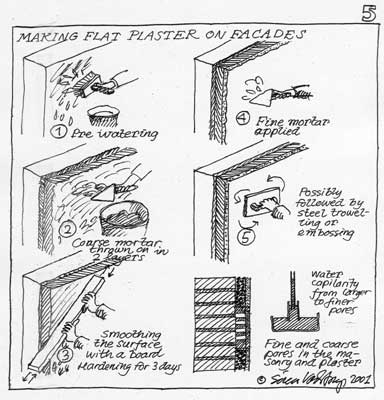

Making flat plaster

Flat plaster has to be made in three

coatings or layers as shown on drawing no. 5:

1 A thin, rough backing coat of

hydraulic lime-mortar with quite coarse sand, thrown on the masonry, keeping

a fairly rough surface. This layer should harden 2-3 days.

2 A 2-3 cm thick second coat of

coarse mortar, drawn to an even layer and after that allowed to harden

for one week.

3 A 1 cm thick finishing layer with

fine grained sand, thrown on and scoured to an even coating.

As water inevitable moves from larger

pores to smaller, a construction with fine pores on larger pores, this

construction ensures, that intruding water will move out again relatively

fast.

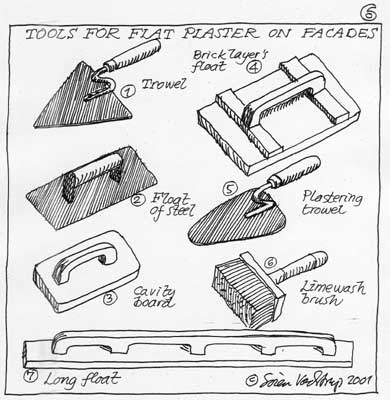

Tools and utensils

The tools and utensils for the flat

plaster are shown on drawing no. 6 and for the flat plaster decorations

on drawing no. 7. The latter are various scraping irons, special spoons

and awls etc. It is important to be very choosey and specialized in selecting

the tools - not just to chose the first and the best.

To the utensils belong various fillets,

a drawing, impregnated with shell-lacquer, and provided with a lot of holes

along the lines of the figures. A so called ponse, which is used for transferring

the drawing to the plaster-ground.

Making scratched stucco-decorations

Scratched stucco pointing, also called

"the poor mans ashlars" is made in the still wet third layer - after the

scouring of the surface. The geometry of the decoration is drawn with an

awl with "light hand". Resting on a wooden list or lath, held by one hand,

a special mason's drag forms a sharp "pointing" imprint in the wet mortar.

The pointing is usually a V-shape, but can also have a square cross section.

Making protruding pointings

Protruding pointings are also made

in the still wet third layer of a flat plaster coat. Here the geometry

figures are scratched with a special iron, held perpendiculary to the surface

and making a slight uneven V-trace, 2-3 millimetres deep.

After hardening for a week of the

plaster, the protruding joints are added in hydraulic lime mortar (1:2:9)

with a special shaped pointing-iron/jointer. The tool is mainly drawn by

hand, resting on a horizontal wooden float, where a pile of mortar is placed.

The consistency of the mortar has to be very precise, both to achieve straight,

precise and sharp-angled pointing and to avoid stains or patches from the

mortar on the rest of the plaster surfaces.

Making inlay/intarsia plaster

decorations

Inlay/intarsia plaster decorations

are also made in the still wet third layer of a flat plaster coat. The

name means "inlay" in Italian, and in this technique specially coloured

mortar is inlayed, in scratched grooves in the fresh mortar.

The decoration is drawn on the surface

in free hand with an awl or the decoration is transferred to the surface

from a drawing via a ponse - a shell lacquer impregnated cardboard, provided

with a lot of awl holes along the outlines of the drawing. With a little

un-tight linen bag (ponse bag), filled with charcoal-dust, the black powder

is sprinkled over the ponse to mark the outline of the decoration at the

wall through the pricked holes in the paper.

Another method to transfer the decoration

to the wall, is to make a overlay drawing, a so called calque, on a piece

of paper, from which it is possible to scratch or trace the contours of

the ornament with a metal pin, through the paper.

After this the composition are scratched

in the wet mortar with a special iron, held perpendicular on the surface,

but this time making an even and square groove, 2-3 millimetres in

the surface.

Still while the mortar is wet -

that means during the same day, the groove is filled carefully with a specially

prepared coloured air lime mortar, quite "dry" in the consistency, but

applied "wet-in-wet". The mortar must be prepared of wet slaked air lime

and very fine sand (0-4 mm) 1:3. The tool for this work is a spatula or

a palette knife.

After filling the groove with coloured

mortar, the surplus mortar is cut away with a knife, so the surface is

exactly at the same level as the plaster-surface. The surface is furthermore

smoothed and straightened with a spatula.

Making sgrafitto decorations

Sgrafitto means scratching or scraping

in Italian - and that is what the process is about. In sgrafitto the hardened

but well pre-watered second layer of rough plaster surface is applied a

2 cm thick layer of a strongly dark coloured lime mortar. The colours can

be charcoal or lampblack, used directly as filler-material in the 1:3 air

lime mortar.

When this layer, which is smoothened

with a wooden float, is still wet, a new 3-8 millimetres thick layer of

white of bright coloured air lime mortar. The pigments can be ground chalk,

whiting or zinc-dioxide. The sand and the chalk has to be delicately fine

grained, to ensure that the surface can be glazed very smooth and even.

Again the geometry or composition

of the decoration can be transferred to the still wet surface by free hand,

with a ponse-drawing, or with a calque.

Still while the mortar is wet, all

the edges of the figure are cut free with a knife or a spatula. It is important,

that the cutting edge forms an oblique angle, both to obtain the sharpest

possible outlines and to keep the rain water from intruding the mortar

layers. After this the rest of the mortar between the lines are scratched

away with special tools.

By this process the dark/black under-mortar

is detached and visible as black/dark drawings or figures in the white

surface-layer.

More advanced sgrafitto-decorations

can be made of up till 4-5 thin layers of mortar in various colours, but

the main technique is made of one dark and one light layer.

Making al fresco plaster decorations

The last decoration technique on

flat plaster to be mentioned here is al fresco plaster. Again the name

is Italian and means "In the fresh (wet) mortar". Even on exterior facades,

al fresco decorations has a quite good durability, but will often be placed

under a large eaves or half roof.

The construction of the ground for

the al fresco are made as described under flat plaster (Drawing no. 5).

But instead of three layers, the ground is built up with 5 to 6 very thin

layers (3-4 millimetres), with finer and finer sand - ending with fine

grained marble dust in the last layer. In this decoration technique the

layers must not carbonate, but on the contrary has to be applied žwet-in-wetÓ,

in one continuous process. To prevent shrinkage cracks, the layers are

beaten hard with a wooden board or the like, to make the plaster as tight

and firm as possible. Even though it is necessary to scratch the surface

slightly with a comb, before applying the next layer, to improve the binding.

The colours for the mural paintings

are made of lime water, mixed with fast pigments and stored for 24 hours,

to be totally soaked.

Again the figure or geometry of

the decoration has to be drawn on the wall or transferred very qiuckly

to the finishing coat of very fine mortar, with a ponse or a calque, and

then, continuously at this point, the fresco painting is made as quick

as possible on the still wet mortar. Here no mistakes or regrets are allowed,

as the lime colours intrudes into the mortar surface and fix immediately.

It is only possible to make a painting

as large as the prepared mortar ground - a so called "day's work", but

on the other hand, it is not possible to continue the next day on the "old"

mortar layers from the day before. They have to be pulled down and new

ones constructed again all from the very start.

Index

|