Working

Techniques and Repair Methods for Plaster Decorations on Facades

By: Søren Vadstrup

5. Sunken batten

decorations in plaster on facades

Stucco, ashlar and imitated/artificial

stone on facades can be made in several ways, but the sunken b atten technique,

which is described here, is definitely the masons work, while the technique

of making ashlar with running moulds is mainly carried out by the stucco

workers - sometimes by the masons.

Sunken batten decorations is made

of specially formed battens, which make an imprint in the wet mortar, and

by this, when the battens are removed again, imitating pointings or forming

edges of natural stone work.

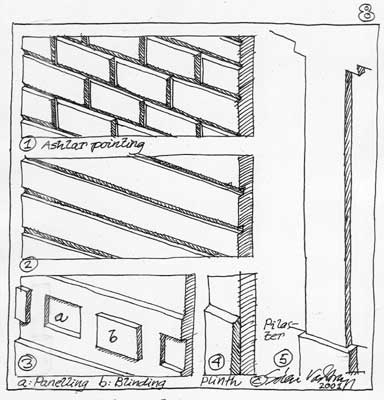

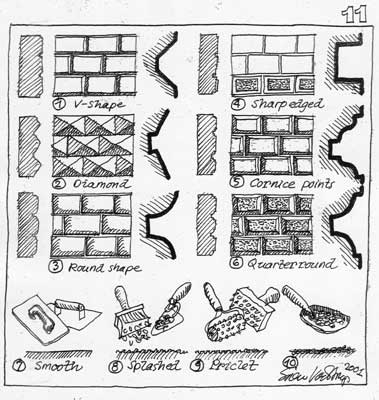

Drawing no.8 shows the different

varieties of relief imprint decorations. Most common are ashlar decorations,

but also other possibilities are indicated. Ashlar can have various appearances,

as shown on drawing no.11, both regarding the relief in the pointing grooves

and the character and structure of the surface.

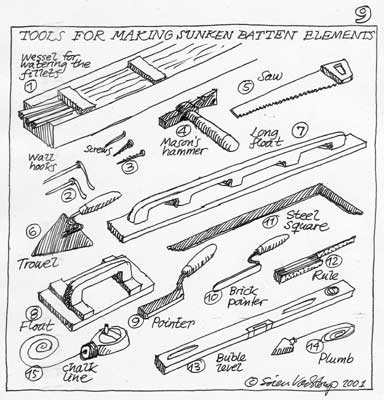

Tools and utensils

The various tools, both for carrying

out the ashlars and for the surface treatment, are shown on drawings no.

9 and 10.

Materials

The materials are hydraulic lime

mortar and on buildings after 1860 often Portland cement mortar. To day

we recommend hydraulic lime mortar (1:2:9) both for making new ashlars

and for the repair of old decorations, because the old remaining cement

materials are now so weakened that insertions with new, modern cement mortar

will cause problems.

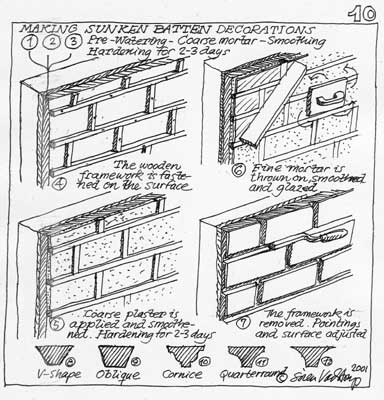

Making sunken batten decorations

The backing coat for the sunken batten

plaster decoration has to be 2 layers of rough mortar, thrown on well watered

masonry, smoothened and after this hardened for 2-3 days or a whole week.

A lot of battens are planed to obtain

the right shape for the revers imprint of the pointing grooves. After this

the fillets are soaked, totally sunken in water for a couple of days. The

shrinkage of the wooden battens after the hardening of the mortar and the

drying of the wood makes it possible to remove the battens again without

spoiling the edges of the pointings. Besides this the battens must have

a conical and chamfer shape.

When the backing is ready, the battens

are placed and fixed to the facade, in the wished pattern (Drawing no.

10). After a thorough watering of the backing coat, a layer of rough hydraulic

lime mortar is thrown on the surface and smoothened, approximately 1 cm

under the outer level of the battens.

After a weeks hardening the ground

is thoroughly watered and a finishing layer of fine grained (0-4 mm sand)

hydraulic lime mortar is thrown on. Now the surface is smoothened and glazed

very carefully, to the same level as the outer level of the battens.

While the mortar still is wet, and

the battens still at its place, the desired surface structure is carried

out, except the stone carved surface (no. 5).

After a weeks hardening the wooden

skeleton is removed very carefully, in order not to destroy the edges of

the pointing profiles. The screw holes, possible missing parts or air holes

are repaired immediately, if necessary with special shaped jointer.

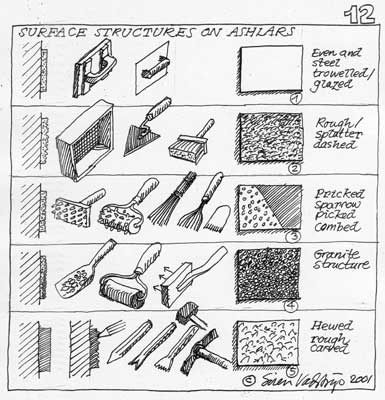

Surfaces structures on ashlars

1 Glazed or polished surfaces are

made by a smooth wooden float and a metal board

2 Splatter dashed surfaces are made

of a relatively rough lime mortar, thrown on the surface through a rough

sieve. In order to appear as natural as possible, the mortar ought not

be adjusted after the application.

3 Sparrow picked or combed/brushed

surfaces are made with special tools as shown at the drawing, while the

surface mortar is still wet. The comb or besom is often draw slantingly.

4 Granite gravel surfaces are made

of selected granite gravel, either rough cut and sharp rubble or small

round gravel, which is thrown at the wet mortar or pressed or pushed in

place. To fix the gravel, it is furthermore pressed in the ground by a

roll or a wooden beater.

5 Rough carved surfaces are made

by leaving the surface 2-3 cm higher than normal. After one week of hardening

the surface is carved with stone carving tools: Flat chisel, tooth chisel,

point chisel, flat hoe and tooth hoe, for different surfaces.

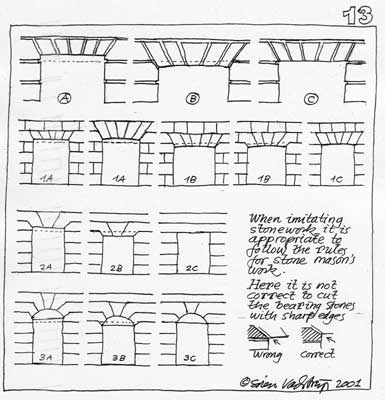

Lintel-constructions

The lintel-constructions is an important

element of ashlar decorations on facades in connection with holes for windows

and doors. The lintel can be horizontal or curved/bowed.

In the first place it is important

that the horizontal lintels are not made totally straight, but constructed

with a very small bow upwards, only 1 cm, because if not, they will seem

to be "hanging".

Secondly, when imitating stone work,

it is necessary to think and to "copy" how a stone mason would construct

the same detail in real stone. To be able to receive the pressure from

he load, the corner stones are cut without sharp edges, which tend to break

off. Therefore the upper edge of the window- and door holes are often raised

or lowered approximately 5 cm in proportion to the horizontal joints -

to prevent sharp and therefore weak edges at the particularly loaded bedding

stones in the upper corners.

This gives some varieties in the

design, depending of the hight of the lintel stones as shown on drawing

no. 13.

If an existing ashlar does not have

these details, it must not be changed, but kept exactly as it is now. Many

lintels on existing old buildings are made in level with the horizontal

joints. But the right way to construct this detail is to imitate, not only

the external likeness, but also the stonemasons craftsmanship and natural

and functional constructions.

Index

|