Working

Techniques and Repair Methods for Plaster Decorations on Facades

By: Søren Vadstrup

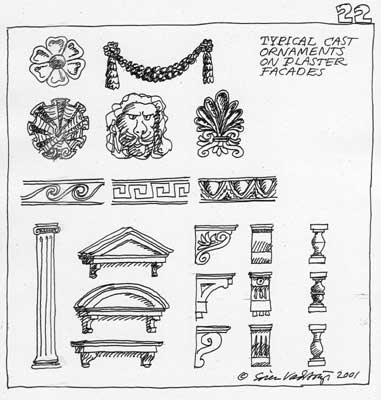

8. Cast decorations

in plaster, gypsum or cement on facades

Quite a lot of the decorations on

plaster facades are cast in Portland Cement mortar, gypsum or other specially

mixed materials and thereafter mounted to the plaster surface.

Portland cement is created among

other things to suite this purpose, but it is hard to believe, that a relatively

weak material as gypsum can last for long time on rain, frost and salt

exposed exterior facades. But experience shows, that cast gypsum decorations

have a surprisingly good durability and can under certain circumstances

last for several hundred years.

The gypsum decorations are in spite

of this mainly reserved to quite flat reliefs or friezes, or they are placed

well sheltered from water under a large main cornice or roof eaves. It

is furthermore very important that the cast gypsum decorations on facades

are surface treated and protected by a layer of linseed oil paint.

A very special material, used in

Britain as early as the late 1700s and still used today is composition

or comp, a very early "plastic" material, consisting of linseed oil, animal

glue, natural resin and clean whiting as the filler. Heat and damp was

used to speed up the curing.

The main material for cast decorations

is however Portland Cement, which appeared as a very popular and used product

for this purpose at about 1860. It is quite often difficult to see, whether

a facade decoration is hand made on the spot or cast and mounted. Only

more close investigations will disclose or verify this. The treatment in

case of damages and deteriorations are quite different.

The cast decorations were often cheaper

than the hand made, as they can be mass-produced and still relatively individual,

because of the huge amounts of products and enormous sales potential. Complete

catalogues with drawings, sizes, variations and prices were sent to the

crafts firms, to the architects and the building owners from the big factories

in each country. Columns, half columns, balconies, balustrades, consoles,

casings, friezes, festoons, medallions, etc. etc.

There are three methods for casting

in Portland cement:

1 Pressed semi-dry casting

method in a rigid reverse piecemould

2 Wet casting method in a rigid

reverse piecemould

3 Wet casting method in a flexible

mould

When recasting old facade ornaments

on historic houses to day, primarily the flexible moulds are used, so only

this method is described here.

The advantage with the semi-dry

technique is, that it is far and away the fastest, as a cast takes 20 to

30 minutes. A wet cast demands a day in the mould to harden.

It is recommended to use ordinary

Portland cement (OPC) for this purpose, in suitable mixes with selected

coloured sand 1:3 - without the many modern adherents and reinforcements

as fibreglass (GRC), PVC and others

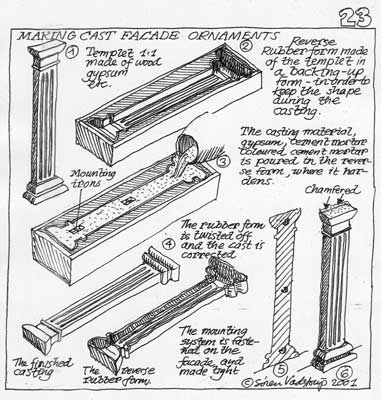

Wet casting with gypsum or Portland

Cement in flexible reverse moulds:

1 Production of a full scale model

in a appropriate material: Gypsum, wood, cement.

2 Making of a negative casting mould

in cement, gypsum or, to day, silicone rubber. The mostly used type is

žopenÓ in the back, only with decorations on the three sides - plus possibly

top and bottom.

3 The casting mass, Portland Cement,

gypsum, more rarely hydraulic lime mortar, is poured into the casting mould.

Irons or other systems for mounting are fastened in the wet and soft material

4 After the hardening the cast element

is removed carefully from the casting mould and possible defects are repaired

or retouched.

5 Finally the cast element is sold,

transported to the building site and mounted at the facade.

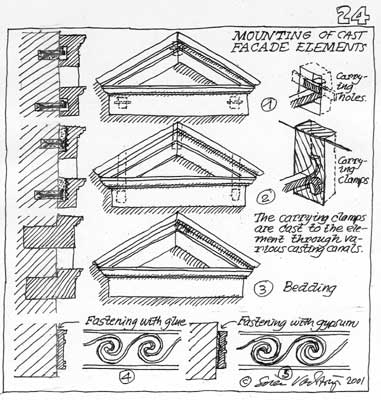

Mounting systems

Drawing no. 23 shows the various

mounting systems, anchors, glue, even simple wet gypsum mass. Other methods

can be used and must be explored from case to case.

The iron anchors cause the heaviest

problems, as they will start to corrode, when possible cracks or gaps allow

water to expose the iron surface. The inevitable result is corrosion which

again soon will cause bursting and breaking masonry because of the expansion

of the iron.

Index

|