Working

Techniques and Repair Methods for Plaster Decorations on Facades

By: Søren Vadstrup

10. Repair on plaster surfaces

and plaster decorations on facades

The deterioration and damages

on facades

Insufficient understanding for and

neglect of the gradual deterioration and damages on the facades are the

causes of long term destruction or even loss of many historic buildings.

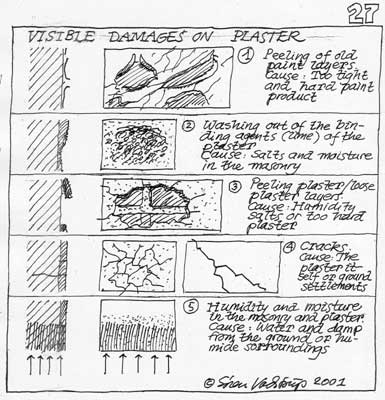

Visible damages

Some of the damages are immediate

visible on the surface. For instance (Drawing no. 27):

1 Peeling paint layers

2 Leaching of the bonding

agents of the plaster

3 Peeling of layers of plaster

4 Small and larger cracks

5 Humid, moist or wet plaster

from ground humidity

Causes of the damages

Most of the deterioration and damages

has 5 causes:

1 Influence of water - and

the consequences or followers of water: Moisture, ice, saltwater, acid

rain. This causes dry rot and fungus in wood, salts in masonry and stones,

frost damages, acid deterioration, algae, dirt etc.

2 Mechanical causes - from

wear, ground decreases, insufficient carrying capacity and wind.

3 Technical faults - from

insufficient constructions: Leakages, insufficient adjoints between materials,

too hard and moisture tight surface treatments or finishing coats, changes

in the physical balance in the constructions.

4 Forced deterioration of

the surface materials due to leakages in the roof, joints, watertight surface

on iron etc.

5 Other causes - incorrect

use and arrangements, neglect of maintenance.

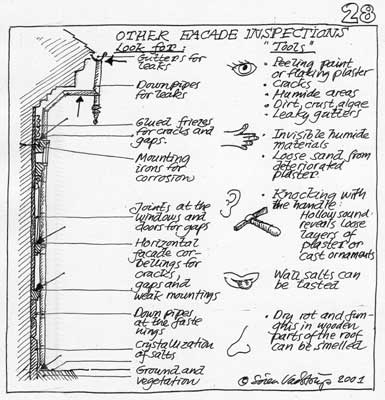

Technical survey on the masonry

But before the restoration of the

facade, the masonry must be examined more closely. This should be executed

preferably by an impartial authority, and not by the craft firm intended

to be involved in the actual work. One or more of the following circumstances

must be inspected depending on the type of construction:

1 Did any constructive circumstances

lead to damages on the masonry like soilage on the facades? Are there constructions

that should be altered?

2. Are the flashings, trims,

gutters and leaders in order?

3. Is the masonry discoloured

and is it necessary to clean it?

If so, an experimental cleaning

must be executed well in advance of the renovation to find the suitable

method of cleaning, for instance by water jetting etc.

The most considerate method towards

both masonry and environment should be chosen.

4. Is the masonry coated with

an impermeable paint layer that has provoked the damages on the masonry?

If so, the paint-layer must be removed

and replaced by a moisture penetrable type of paint.

5. Is a moisture insulating

layer induced in the footing, or is there any other obstacle for the soil

dampness to enter the masonry?

6. Are there smaller or larger cracks

in the masonry or the plaster?

7. Are there cracks or gaps in the

masonry, where water can enter? For instance in connection with mounted

cast decorations, balconies, staircases, iron rails, iron anchors, wooden

windows or doors, half-timbering, natural stone etc. If so, this can be

dangerous for the facade.

8. Are there evidence of corroded

iron anchors, deeper in the masonry.

9. Is the plaster deteriorating,

peeling, flaking, constantly wet or dose it look "rotten"? If so, there

are probably absorbed salts in the masonry. The plaster must be removed

totally and the causes for the salts, ascending ground-moisture, salt storing

in the building, thaw-salting of the pavement etc. must be removed or reduced

and the salts drawn out of the masonry by packages of distilled water or

a sacrificed layer of lime mortar. A new layer of lime mortar, constructed

as two layers of increasing fineness, is added. These parts of the masonry

cannot be surface-treated with lime wash or paint before all salts are

removed.

10. What design/mixture has the

existing plaster? The plaster repair must always have exactly the same

design/mixture to ensure the same strength, elasticity, sough-ability -

plus colour and grain-structure.

Plastic paint on facades

Frost-bursted joints and tiling

often occur on lime washed facades successively coated with plastic emulsion

paints, cement-based paints or modern silicone paints. Particularly old

houses built with hand moulded bricks jointed with lime mortar are in the

danger zone.

The cause of the damages is often

due to the fact that the new materials used for surface treatment are much

too impermeable which lead to a diminution of the transmission of the natural

humidity and vapour. The humidity is accumulated behind the surfaces from

which it slowly evaporates and crystals will deposit and keep growing.

This is shown by experience and

it is documented by the so-called PAM numbers (value given for pressure

against moisture). The PAM-values of the above mentioned materials are

as follows:

Lime wash:

0,0 - 0,4

Paints based on cement powder

0,8 - 1,0

Plastic emulsion paints

2,0 - 7,0

These numbers emphasize that lime

is the material with the highest diffusion without doubt. The importance

of the open lime surfaces compared for instance to the more impermeable

materials is revealed by all the damages that occurred during the last

few years in connection with the new treatments. Well-harden lime

mortar is furthermore deteriorating if it is inclosed by a material with

a high PAM-figure.

Other damages are provoked by the

water that penetrates from the outside through fine cracks and accumulate

behind the impermeable surface-treatment and does not have the possibility

to evaporate quickly through the dense surface coating. The accumulation

of water in the masonry leads to crystallisations and frost damages during

winter which manifest itself as bursts of joints and formation of stone.

Cleaning for plastic paints etc.

The cleaning of masonry previously

treated with plastic emulsion paints or materials based on cement must

be done down to the firm ground.

Cleaning is done with low-pressure

jetting, where it is possible. The work must be executed with great care

in order not to damage the masonry additionally by admitting to much water.

A possible mixture of sand and a successive water jetting should not be

too hard as it will damage the fire coating of the tiles. In that case

the surface of the bricks will be damaged and consequently they will

absorb much more humidity than before. It is recommended that experiments

are made in every single instance until the correct method is found.

Building parts, windows, doors,

cornices etc. that are not to be cleaned must be covered properly before

the treatment is initiated.

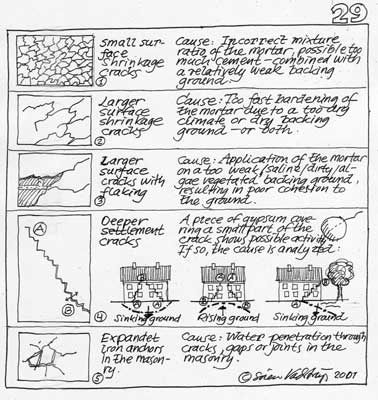

Assessment of cracks

The crackings may appear both in

an early state after the coating of facings, which is the most frequent

situation, or it may appear much later, many years after the finishing

of the building.

The crackings on plaster can, as

shown on Drawing no. 29 be grouped in:

A: Surface crackings

B: Deeper crackings

or slots

Surface crackings

Surface crackings do not overcome

the thicknes of the single or multiple layers. In general they do not follow

a specific direction. They may appear in any direction and they often give

origin to closed cracking lines, such as large cells with big or small

dimensions.

Surface crackings is generally due

to wrong application of the coatings.

1 The use of mortars with unsuitable

composition or mixture will cause crackings as shown in picture no. 1.

2 The application of mortars on

too dry or hot surfaces causes too quick stiffening and the consequent

laminar retraction, shown in picture no. 2

3 The application of renderings

on dirty surfaces with any kind of fungi, powver, or under some active

chemical decomposition, give orign to a kind of cracking followed by detachment,

as seen on picture no. 3.

Deep crackings

Deep crackings attain deeper in

the walls, overpassing the coating and attaining as well the composing

elements of the wall supports, bricks, stone blocks, hydraulic binding

and reinforced concrete.

Deep crackings also differ from

others for their specific direction and location of specific points of

the building architecture, as seen on picture no. 4.

Deep crackings are generally due

to structural movements, mostly downwards, in the foundations of the facade.

The deep crackings and the surface

crackings may have the same apperance when they are not coincident at the

surface of the rough wall and in the coating. This happens when the wall

detaches itself from the coating.

Another type of deep cracings is

due to the expansion of corroded iron anchors, situated deeper in the masonry.

Picture no. 5.

Examination

The method of examining the conditions

of a cracked plaster/rendering is by knocking/percussion on the surface

with a wooden shaft/handle of a hammer.

- a clear and open sound indicates

adhesion of the plaster to the support

- a hollow and deep sound indicates

detachment from the support

Repair of cracks

If the following conditions occur

in a new rendering, it will be sufficient to fill up the crackings with

a thin past of the binder, used in the rendering:

- the affected area is limited

- the crackings are small

- the dimensional stability has

been checked

- a finishing layer, limewash

or painting is to be applied.

If the affected area is wider or

if the crackings overpass 2 mm, the new rendering should be taken of and

a new layer applied, with the right composition or mixture and the right

construction.

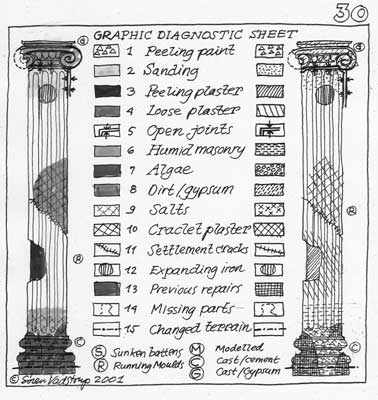

Graphic diagnose sheet of the

deterioration and damages

In order to produce a documentation

of the technical state of the facade, and at the same time get an overview,

it is recommended to work out a Graphic diagnose sheet, as shown at Drawing

no. 30.

She sheet can be made with colours

or with graphic symbols, covering the most common types of damages on plaster

on facades.

Photoserie III: Damages on plaster

decorations:

A Flaking of plaster layers

B Detail of flaking

C Gaps in joints between cement

elements

Historic research on the masonry

Besides these technical examinations

of the masonry it will be relevant to investigate the history of the facade,

that is the previous colours, previous repairs, previous alterations previous

plaster coats - or other surface-treatments.

The sources for this can be written

documents or records in archives, old drawings, paintings or photographs,

but primary, careful investigations and observations on the facade of traces

of colours etc.

Restoration attitudes

1 First of all, the original parts

of the building must be preserved and protected by restoring the building

as carefully as possible. Repair should be preferred to replacement.

2 The maintenance and restoration

of the building must be carried out with the same traditional materials

and crafts techniques that were used when the building was originally built

3 We must have a thorough understanding

of the materials and constructions, regarding both the weak and the strong

points, in relations to what is required of them. Therefore the restoration

work must be carried out by multi-dicipli-nary ex-per-tise and specially

trained and experienced craft skills.

4 It is important, through the repair-

and restoration work to keep up or improve the architectural entirety of

the facade.

5 When a restoration implicates

severe alterations a brief and concise docu-mentation is required including

for instance descriptions, photos, drawings etc., in case information about

the constructions one day should be needed. The documentation must be available

in a public archive.

The traditional building- and

crafts techniques

The traditional building- and crafts

techniques involve a number of carefully prepared preventive elements to

avoid these life-threatening damages of the buildings. They represent a

kind of natural physical balance, which will be destroyed and causes more

damages, if unconsidered changes are being made.

The traditional building constructions

have 5 preventive elements, which will diminish the chances and cause later

damages:

1 Quality-improvement of

the materials and micro-constructions by the crafts-techniques. Examples:

Hand-wrought iron, quartersawn wood, waterlogged wood, mixing and application

of lime mortar, mixing and application of paint, etc.

2 3-double protection of

critical constructions and elements. Examples: The joint between window

and masonry, the construction of the wooden windows, rust protection of

iron, the tile roof, the plinth/socket-construction, the building of wooden

balks in masonry etc.

3 Sacrificial layers: On

very critical points, the traditional constructions operate with sacrificial

layers or elements, which are easier to change or repair than the vital

elements. Examples: The plinth-mortar, the mortar-joint on windows, the

linseed oil putty on windows, the traditional paints on exterior wood,

the horizontal bottom- or top boards in wooden constructions, etc.

4 Maintenance-signals: The

traditional materials and constructions send out distinct ėmaintenance-signalsî,

when they need to be maintained. Examples: Linseed oil paint and other

traditional paints, lime wash, tile roofs, windows, exterior wooden boards

etc. It is very important to know these distinct "signals" and to read

them right. Uninformed people often interprete these as serious damages,

needing to be renewed - and not just maintained.

5 Repairable elements: The

traditional materials and constructions are ėrepairableî, which is a very

important quality. If something happens, you can repair parts or whole

elements. This gives these elements, for instance wooden windows, a life-long

durability. There are thousands of examples of wooden windows lasting more

than 200 years - and still in an excellent state of preservation!

There is a lot of examples of how

more knowledge and awareness of these 5 important, but often forgotten

qualities of the traditional building materials, building constructions

and crafts techniques could save both the house-owners and the different

countries quite a lot of money.

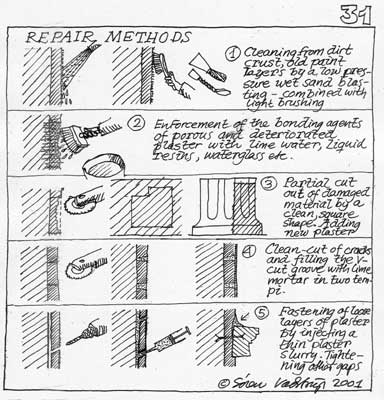

Repair methods

After a cleaning has taken place

at the facade a repair of defective and frost bursted bricks has to be

executed: Defective stones are cut out and new hand moulded or sandfaced

tiles are bricked in which lead to the best adherence to the following

lime wash. Frost bursted joints are scraped out until firm mortar, min.

3 - 4 cm, and a new joint filler is applied.

Any parts with loose plaster, cracks

etc, are cut of. Plaster or mortar joints repaired with cement or mortars

containing cement must also be cut out and replaced by lime mortar, as

the lime does not adhere sufficiently to cement-based surfaces.

The surface of cement-based mortar

is tight sheets of silicates absorbing humidity behind the surface and

a humidity absorption that slowly evaporates. The more open lime mortars

quickly gives off the moisture again. Lime washed surfaces on which repairs

are made with cement mortar will appear very stained in damp weather. Cuttings

up to the existing original, but appropriate plaster shall always be made

with right lines and right angled corners.

After a cutting out of bricks and

joints down to a firm ground the masonry is carefully cleaned of remains

from the mortar, dust etc. and water is sprinkled on until the surface

is saturated as much as the bricks and joints will be able to absorb a

little of the mortar water. The joints are completely filled and a backfill

may be necessary too and eventually all joints are compressed with a brick

jointer.

Technical principles for plaster

repair

When carrying out repairs on existing

plaster on masonry or making a new layer of plaster on old buildings, there

are 5 main principles, which have to be followed:

1 All repairs on existing plaster

on masonry or new coats of plaster should use an air-lime-mortar, without

hydraulic additives or cement, or, on certain extreme positions,

a slightly hydraulic mortar. This goes also for repairs of old cement-plaster.

2 The plaster shall be an exact

copy of the existing plaster, regarding roughness, colour, surface-character,

traces of the tools etc. The mason has to make a sample for a critical

comparison, before the whole work is started. Certain research-institutes

can analyse the old plaster and determine the type of the binding agents,

the sand and other additives.

3 Before adding new plaster, the

masonry has to be cleaned of dust, dirt and detached parts by brushing

and subsequently the surface is watered carefully with plain tap-water.

4 Layers of plaster shall be carried

out in three coatings or layers:

A: A rough but thin ground

layer of air lime mortar 1:3 (or hydraulic lime-mortar 2:1:9, 1:1:6 or

1:2:9 - depending of the deterioration, weak- or hardness of the background

masonry) with quite rough gravel, thrown on the masonry, and left fairly

uneven.

B: After hardening: a 2-3 cm second

backing coat with coarse gravel, thrown on and then drawn to an even layer,

and after that allowed to harden for one week.

C: Then followed by a very fine

finishing layer/coat with fine grained sand, also thrown up and drawn to

an even coating.

The thickness of the layers must not

be superior to 2 cm, as thicker layers will cause thermal differences and

internal pressure between the interior areas and the area more exposed

to the weather conditions, where the water evaporation and the quick cooling

of the mortar occurs. This favours the retraction effect with inevitable

uprising of crackings.

5 A good and lasting result implies

previous, appropriate interventions against structural settings in the

masonry, ascending ground moisture or hygroscopic salts.

Demands for weather and temperature

Mortar-repairs must under ideal

circumstances take place during a relatively humidity in the air at 75-95

%. The temperature should be minimum +5 Celsius and maximum +18-20 Celsius.

A total absence of wind is also recommendable.

Materials

See chapter

2

Index

|