Working

Techniques and Repair Methods for Plaster Decorations on Facades

By: Søren Vadstrup

6. Running mould decorations

in plaster on facades

The main cornices, the architrave

and horizontal friezes, the window- and door casings and possible half

columns are typically made by running mould. But also ashlars can be constructed

this way.

Materials

Running mould decorations on facades

are constructed of air lime mortar or hydraulic lime mortar. After 1860

also Portland cement mortar is used.

To day we recommend the use of air

lime mortar (1:3) or hydraulic lime mortar (1:1:6 or 2:1:9) both for making

new Running mould decorations and for the repair of old decorations, even

if they are originally made of cement. The old remaining cement materials

are right now so weakened that insertions with new, modern cement mortar

is not appropriate.

Tools and utensils

Running mould are made by a sheet

zinc mould, mounted on a wooden sledge, which is able to ýRunningţ or glide

along the facade, via horizontal or vertical rails and guides, fixed to

the facade. Furthermore special trowels and boards are necessary.

Making Running mould main cornices

and friezes

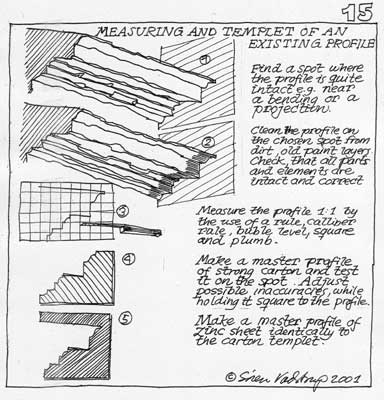

At first it is necessary to make

an exact drawing 1:1 of the profile or mould of the cornice or frieze.

If an existing cornice is repaired or replaced, the old and original profile

must be painstakingly measured and recorded - on a place, where the profile

is most best preserved and correct.

To verify the exact shape, a accurate

templet is made in paperboard, and tested and corrected at the spot.

Note that the main cornice are often made with a little oblique drip (under

carved) internally, to prevent water drops from "hanging". This must be

carefully copied.

It is on the other hand quite important,

that the running mould decorations, especially the main cornices, have

good proportions, so in glaring cases, it is allowed to improve the shape.

The next step is to make a accurate

sheet zinc mould of the same shape as the cardboard templet. After this

a 1 cm smaller sheet zinc mould is made for the first, muffle running mould.

Both sheet zinc moulds are nailed to a piece of board or plywood, cut out

2-3 mm smaller than the sheet zinc mould, and provided with a chamfer towards

the profile.

The wooden piece with the sheet

zinc mould is now firmly mounted to a wooden sledge with a special lock

wedge and two shore lists, fixed with screws.

Now two wooden rules are mounted

at the masonry, following the future lines of the cornice, frieze or casing,

at the facade, and adjusted in proportion to the right height and course

of the running mould sledge. As the mortar layer must not be more than

5 - 6 cm thick, all larger running mould decorations must have adequate

corbellings of bricks or stone in the masonry. Therefor it is necessary

to test the running mould sledge at the spot, in order to ensure, that

the applied mortar layer everywhere will be between 3 - 5 cm thick

After plentiful pre-watering of

the backing, coarse hydraulic mortar is thrown on, and the small sized

reverse running mould drawn with the slanting edge pointing backwards.

This is done several times, until the shape is complete, according to the

small mould. If the surface is very smooth, it will be necessary to scratch

small grooves in it.

After 2 - 3 days of hardening, preferably

more, we are ready for the finishing coat. The mortar for this must be

made with air lime, wet slaked for at least 3 years, mixed with very fine

sand (0-4 mm), in proportion 1:3. Mixing time: 20 minutes.

The ground is pre-watered and the

fine grained mortar thrown on and treated with the larger reverse running

mould mounted at the sledge. When the shape is completed, a finish coat

is applied, mixed in the proportion, lime sand 1:2, while at the same time,

the running mould is drawn the opposite way - with the slanting edge

pointing forward. This creates a particular hard, smooth and weatherproof

surface.

Photoserie I: Making running mould

friezes

A Setting

up the wooden roles on the masonry

B Testing

the reverse zinc mould for the space for the corbellings

C Coarse

mortar is thrown on

D The

running mould scrapes surplus mortar off

E Fine

mortar is thrown on

F The

running mould scrapes surplus mortar off and smoothens the surface

G Detail

of the running mould

H Detail

of the running mould

I Detail

of the running mould

It will often be necessary to make

the last 10 cm at the end of the running mould decoration ýby handţ, as

the sledge has only a certain length. This is done with a collection of

special wooden floats - never with a sponge, as this will damage the edges

and spoil the lines.

The reason why the running mould

decorations are made in two separate operations - with two sheet zinc reverse

moulds of different size, is to prevent the small shrinking cracks in the

surface, which inevitably will occur if thicker layer of mortar is applied

continuously "wet-in-wet". By laying a relatively thin finishing

coat on a thicker, but hardened ground layer, the shrinking cracks in this

will be filled, covered and minimized. As these cracks, even if they are

quite small, often causes increased deterioration and approaching damages,

especially on decorations exposed to rain, this more complicated

procedure is absolute worth while.

Running mould decorations are sometimes

pre-fabricated at the workshop, cut in suitable elements, transported to

the building site and mounted here like the cast decorations.

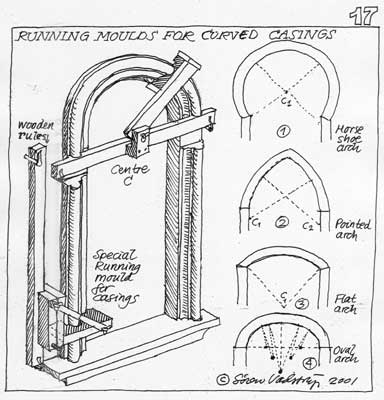

Making curved running mould decorations

Door- and window casings are sometimes

curved, which is also possible to make with the running mould technique

as shown on drawing no. 17.

The straight parts are made with

a smaller running mould sledge, thus enabling the mould better to reach

the often sharp bottoms. To make the curved parts, the sledge is mounted

on a special board, fastened at the constructed centre for the curve, arch

or chord - sometimes more than one centre is necessary. The centre point

is fixed with special arrangements.

Another method is to set up specially

curved rules - and draw the running mould along these. They can describe

any possible curved form.

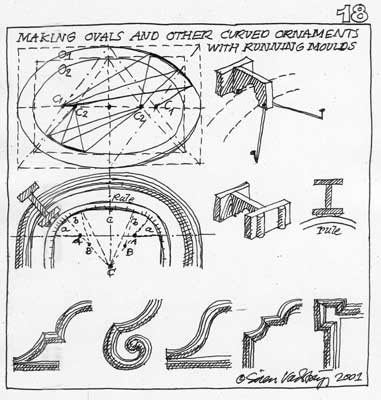

Other curved ornaments on facades

made by running moulds

A lot of other curved ornaments on

facades could be made with the running mould technique, using various types

of running moulds: elliptical, oval, convex-concave, cornice-shaped etc.

Very often these decorations are made by running moulds at the workshop

and, after the hardening, mounted at the facade in suitable pieces, but

they could also be made in situ.

The methods are either with strings

or curved rules - combined with specially designed running moulds in each

case - followed by hand modelling with special floats and trowels.

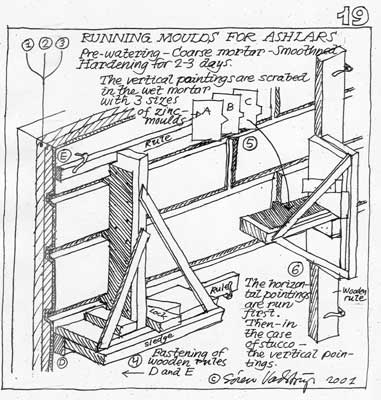

Making running mould stucco and

ashlar

As mentioned above, artificial stone

walls and ashlars are often carried out with a running mould technique,

as shown on drawing no. 19. Here it is only necessary to fabricate one

sheet zinc reverse mould, as the running mould and the sledge can be "moved

outwards" in two tempi. This has the purpose to construct the plaster decoration

in 2 various layers of mortar, a rough ground layer, which has hardened

before the second, fine grained finishing layer.

The running mould process starts

with the executing of horizontal pointing grooves. The vertical traces

are drawn afterwards in the still wet mortar. The vertical pointings are

scraped in the mortar, which can be done partly with a scraper, partly

with the reverse running mould, in 2-3 variuos shepes.

The same procedure is followed for

the finishing layer of mortar. Apart from this all the measures and guidelines

described above under running mould have to be followed.

Photoserie II: Making running

mould ashlar

A The

wooden rules are placed on the masonry

B Coarse

mortar is thrown on

C The

running mould scrapes off superfluous mortar

D The

last coat is finished

E The

surface character is made

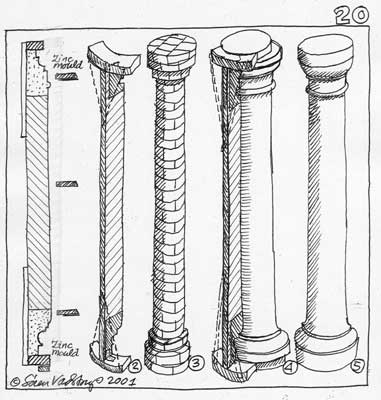

Making vertical running/turning

mould for columns

It is also possible to fabricate

a plaster column or a half column in the running mould - here vertical

turn mould - technique.

The column is constructed in masonry,

including the necessary corbellings, leaving approximately 4 - 5 cm to

a finishing coat of plaster - constructed of two layers of hydraulic lime

mortar. As the turning mould can be moved outwards, by adjusting the slide

pieces, there is no need for two different mould sizes to obtain the previously

described two coat construction of the plaster.

Index

|